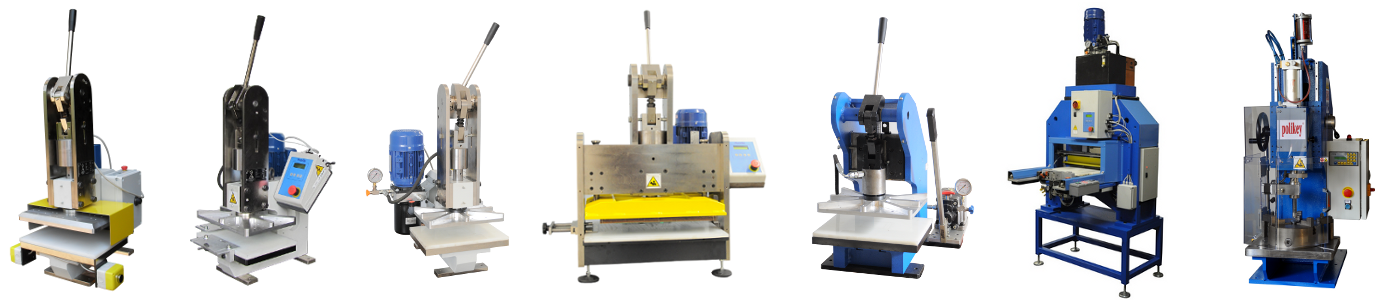

How to choose the die cutter

For an adequate choice of the type of punching machine, suitable for your needs, it is necessary to establish the power to be used for the punching operation of the material to be treated (paper, rubber, leather, etc.).

The thickness and the work to be obtained are the variants to be considered.

These factors help define the force to be applied for each linear cm of cut. Multiplying this value for the development of the profile to be cut determines the power necessary to determine the structure of the die-cutter.

In addition, you can opt for a manual or automatic machine, based on the processing and the product you want to obtain. In the case of small quantities or non-repetitive series, a manual die-cutter can be chosen.

If it is a medium-series production, the choice depends on the quantity of pieces that must be die-cut.

By way of example, we indicate some values that can help you in determining the useful power per linear cm:

300 ÷ 400 pieces now if the die-cutter is automatic, using from 8 to 12 seconds per piece.

120 ÷ 180 pieces now, if the die-cutter is manual.

All machines with an electric pump use a voltage of 230 V, but can even reach 400 V for industrial plants.

Indicative data

Nella tabella sottostante alcuni valori indicativi che possono aiutarvi nella definizione della potenza utile per cm. lineare.

| Material | Power per linear cm |

|---|---|

| -Light leather, faux leather, imitation leather sp. 1-2 mm |

starting from 50kg |

| -Leather sp. 3-4 mm | starting from 100kg |

| Paper, cardboard | starting from 20kg |

| Corrugated cardboard | starting from 40kg |

| Plastic, synthetic | from 30kg to 60kg |

| Rubber | from 30kg to 70kg |

hanks to our experience we are able to make a technical evaluation of the product, to recommend the die cutter that best meets your needs.

Why the toggle system?

Because it allows a considerable light (45 – 50 mm) for the preparation of the work, but reduces the working stroke to the minimum, in any case less than 6 mm, a measure that requires CE regulations to use guards or other safety devices. This reduces the cost and makes the operation simple and quick.

Settings:

– Work quotas: because not all dies are the same, thanks to the adjustment screw on the toggle lever;

a ginocchiera;

-Power: by adjusting it on the hydraulic power unit;

– Cycle time: adjustable on the electrical equipment.

Easy assembly of dies

Given the need to adapt the various dies to the fixing plate, a mask has been created that makes the operation of drilling easier and more precise.